Truckmounted carpet cleaning equipment is designed for high-volume, high-performance operations. It integrates heat, pressure, vacuum, and chemical delivery into one system that runs from inside a service vehicle. For contractors working in residential, commercial, or restoration jobs, understanding how this equipment functions, and the advantages it delivers can help determine whether it’s the right investment.

We’ll break down the working process of truckmount equipment, the components involved, and the measurable benefits it offers in terms of cleaning quality, job speed, and operational control.

What Is Truckmounted Carpet Cleaning Equipment?

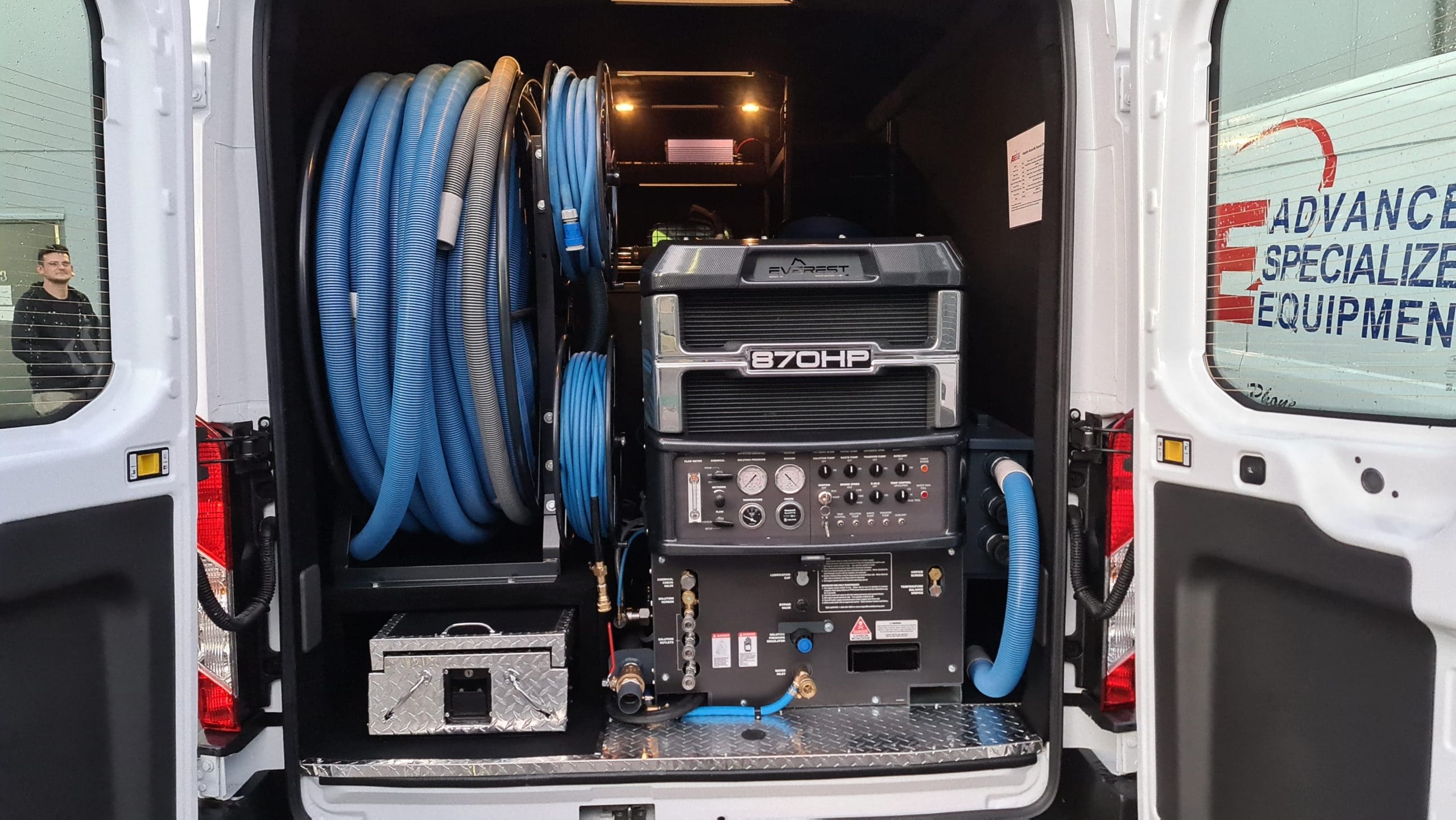

A truckmount system is a self-contained machine installed permanently in a van or trailer. It draws power from an internal combustion engine, enabling it to operate at higher heat, stronger vacuum, and more consistent pressure than portable machines. Unlike portable extractors, which are carried into the job site, truckmounts remain fixed in the vehicle, with hoses running inside the premises.

Professionals use truckmounts when they need consistent water temperature, fast soil extraction, and lower drying times over large or repetitive jobs. This includes carpet cleaning contractors, water damage restoration companies, and commercial service providers. Systems like the Steamway 4100LX, known for dual-operator capability, are widely used where time efficiency and surface depth are non-negotiable.

How Truckmounted Systems Work: Component Overview

The performance of a truckmount carpet cleaning unit depends on the configuration and quality of its components. Each part of the system performs a specific task, and the coordination between them defines the unit’s output.

1. Engine and Vacuum Blower

Truckmounts run off a dedicated engine, either petrol or diesel, that powers the vacuum blower. This blower generates airflow (measured in CFM) and lift (inches of mercury), which extract dirt and moisture from carpet fibres. Unlike electric portables, which may struggle with long hose runs or dense carpet, truckmounts maintain suction strength across extended distances.

2. Water Pump and Pressure Delivery

Water is drawn from a clean water tank or an on-site supply, then pressurised through a high-output pump. Most truckmounts deliver between 500 to 1200 PSI, with some capable of even higher output for hard surface cleaning. This ensures deep solution penetration and effective agitation during pre-spray or rinse stages.

3. Heat Generation

Truckmounts typically heat water through a heat exchanger (engine exhaust or coolant), a propane burner, or a diesel burner. Water temperatures can exceed 220°C in some systems. This heat not only breaks down soils but also accelerates drying time by reducing the moisture left in the fibres.

4. Chemical Injection System

Inline chemical systems allow precise control of detergents or rinsing agents injected into the solution line. Technicians can adjust dilution based on carpet type or soil level, making chemical use more efficient and consistent.

5. Recovery and Waste Tank

After cleaning, the vacuum system recovers soiled water and stores it in a sealed waste tank. The tank’s filtration system separates foam, solids, and debris to protect the blower and maintain suction consistency. Tanks are manually emptied at the end of each shift or job run.

To see how this system integrates into a mobile work unit, visit our Vehicle Fit-Out section, where you’ll find the components installed in actual carpet cleaning vans.

Truckmount vs Portable: What’s the Real Difference?

While portable units have a place in small or multi-story jobs, they can’t compete with the consistent heat, vacuum, and recovery speed of a truckmount. Let’s look at a few critical differences:

- Heating Power: Truckmounts maintain water temperature above 90°C throughout the job. Portables often lose heat between fill-ups.

- Vacuum Lift: Truckmounts operate at 10–15 inHg vacuum lift or more, while portables rarely exceed 8–9.

- Pressure Consistency: Truckmounts hold stable pressure across long hose runs. Portable PSI drops with resistance.

- Drying Time: Less water left behind means carpets cleaned with truckmounts typically dry in half the time.

- Setup Speed: With everything mounted in the van, setup and pack-up are faster, especially with hose reels installed.

While portables may work for certain domestic or apartment jobs, truckmounts outperform in speed, depth, and reliability.

On-Site Benefits for Technicians and Operators

Using a truckmounted system changes how technicians approach daily work. For operators managing multiple jobs per day, several advantages become immediately clear:

- Equipment stays in the van, only hoses and tools go inside.

- There’s no need to carry 40–60 kg machines across thresholds or stairs.

- Chemical use becomes more consistent with inline metering.

- Heated water improves stain removal without needing additional chemicals.

- Jobs can be completed faster, freeing up time for more bookings or an early finish.

When combined with a well-structured maintenance plan, truckmounts provide consistent performance over thousands of operating hours.

Customer Experience: Better Cleaning, Faster Drying, Fewer Complaints

From the client’s perspective, the difference is noticeable. Truckmounts deliver stronger stain removal, fewer resoiling issues, and shorter downtime. For high-traffic offices or restoration jobs, the faster drying time is a major advantage.

Many contractors report fewer call-backs and complaints when switching to truckmounts. Odours, pet contamination, and persistent wicking are reduced thanks to hotter rinse water and stronger extraction. The net result is more trust, better reviews, and higher customer retention.

Understanding the Financial Return of a Truckmounted System

The upfront cost of a truckmount can be substantial, but it should be viewed in the context of return on productivity. A typical portable user might service 1–2 jobs per day. With a truckmount, 3–5 jobs are manageable due to time saved on setup, drying, and pack-down.

Benefits include:

- Higher job capacity = increased weekly revenue

- Lower chemical use per job = cost control

- Longer equipment lifespan = lower annual capital replacement

- Improved operator health = reduced downtime or fatigue-related injuries

Many of ASE’s Business in a Box clients report reaching profitability faster due to truckmount ROI and reduced operational stress.

Installation, Training, and Support from ASE

Truckmounts require correct installation. Fuel lines, venting, mounting brackets, and electrical isolation must all be built to exact standards. ASE provides full integration services, including floor sealing, safety systems, and vibration-isolated brackets.

Our team also offers operational training through Interactive Training International (ITI), giving your staff the ability to use and maintain equipment from day one. We support all major truckmount brands and maintain parts, accessories, and backup equipment if your unit needs service.

Should You Upgrade to a Truckmount System?

If your current setup limits job volume, slows down cleaning time, or causes repeat complaints, a truckmount system is worth considering. Operators dealing with:

- Large commercial clients

- Multiple technicians in the field

- Water damage and restoration jobs

- Recurring deep-clean contracts

…will benefit from the heat, pressure, and productivity only a truckmount can provide.

To explore current truckmount models, or contact us for a quote on installation and fit-out.

Final Thought

Truck-mounted carpet cleaning equipment is more than a tool; it’s a scalable platform for contractors who want faster performance, cleaner results, and less downtime. With the right system and support, the investment becomes a long-term gain in revenue, reputation, and operational control.

To discuss your requirements or learn more about our systems, call 1800 068 901 or visit Advanced Specialized Equipment.